2016 Cobra Jet Build ~ Born to be Wild

2016 Cobra Jet – How Ford Performance builds a factory-engineered, 8-second drag ’Stang

FLAT ROCK, Mich. Following in the rich tradition of previous Ford factory-built Mustang race cars, such as the 1968 Mustang Cobra Jet, the Mustang Boss 429 and the FR500S Mustang Challenge car. Ford Performance, Ford’s Flat Rock Assembly Plant (FRAP) and Watson Racing have started work on another 50-unit Mustang Cobra Jet production run for 2016.

Back in 2005, Flat Rock Assembly (then-known as AutoAlliance International, or AAI) started building the S197 version of the Mustang and to date has produced more than 1,500,000 units. The new-for-2016 S550 Mustang platform proved to be challenging for all members of the Cobra Jet team, but the end product proved out the skill and determination of every team member involved with the build.

While impossible to build on the high-volume FRAP main line, the 2016 Cobra Jet “body-in-white” was built and painted on the FRAP body shop/paint line and the final “build out” was finished at the Watson Racing build facility in Brownstown, Michigan.

2016 Cobra Jet starts out life as a “prepped” body-in-white S550 Mustang. Before arriving at the Watson Racing build line, a 2016 Mustang shell was produced on the main FRAP body line and dipped in an e-coat primer to prevent panel corrosion.

2016 Cobra Jet Build – By Steve Turner SVT Performance

Photos courtesy of Ford Performance

The racing season will be here before we know it. Fortunately, for the lucky 50 buyers of 2016 Cobra Jets, some of those cars are built while the others will be assembled soon. We recently got a look at the process creating these impressive Ford Performance Racing Parts machines, and it’s a little bit different to accommodate the nuances of the S550 platform.

Inside Watson Engineering / Watson Racing >>

The latest Cobra Jets begin life as bare bodies constructed alongside their street-going cousins at the Flat Rock Assembly Plant in Flat Rock, Michigan. These bodies are transported to Watson Engineering for the installation of the roll cage and four-link rear suspension. The latter operation necessitates cutting out a lot of the trunk floor.

“We had a couple challenges this time that are new; mostly because the car has an independent rear suspension. Final assembly was at Watson Engineering, which is the same as we did in 2014,” Ford Performance Drag Racing Parts and Competition Manager Jesse Kershaw explained. “The difference this time is in the past the body comes from the plant, would come to Watson, get the roll cage put in it, then back to the plant for paint. Then it was ready for final assembly. For the 2016 model there were some challenges to putting the live axle in the body that didn’t allow us to do all the body modifications before it got painted.”

Because installing a solid rear axle and a four-link in place of the factory independent rear suspension means removing a lot of the existing structure in the back of the car, that meant a car ready for a solid axle couldn’t travel down the paint line at the Flat Rock Assembly Plant. That resulted in a bit more back and forth between FRAP and Watson Engineering for a new Cobra Jet chassis.

While the Cobra Jets move between Ford and Watson facilities for the build, the cars still follow a strict factory build process. This 40-point checklist requires team members to sign off on each procedure.

“It is a little bit different because it has this secondary paint process because the plant has these locating fixtures on the body and some of the things we were putting in were in the way or things that we were taking out needed to be there,” Jesse said. “Now the body comes to Watson and the put in about 70 percent of the cage and rearend mounting. Then it goes to the plant for painting and comes back. Watson then has to put in the rest of it and they touchup the paint there at Watson Racing.”

Once that process is complete, the frame is ready for assembly, and Watson has all the parts in stock to complete the car. All the small parts and the wheels and tires are on site while the engines and transmissions arrive in batches of five so as not to take up too much space. In all the process takes about 11 business days to go from a chassis to a Cobra Jet. However, before the car is deemed ready for sale, it must undergo a rigorous quality control inspection.

“There is an end-of-line inspection where they fire the car up and check for leaks. The various engineers that are responsible for a system sign off on that system. Some Watson representatives also sign off on some of the build quality areas,” Jesse said. “For example, the electrical engineering guy checks the electrical and the calibration guy ensures the car is flashed correctly. Only after everything is signed off will it get released to the dealership.”

Once owners receive their new race cars, they will not only benefit from a factory-engineered race car, but from the things Ford Performance engineers have learned over the years after previous owners have received their Cobra Jets. Almost any conceivable question can be answered by the car’s extensive manual.

After the cage and 70 percent of the rear chassis structure are welded to the bare chassis, these 2016 Mustang bodies return to their birthplace a Flat Rock where they travel down the paint section of the assembly line to receive one of the two CJ color options—Deep Impact Blue or Performance White.

“We have added more and more details to the operations manual. It is over 70 pages. It’s a book. Everything you want to know—every nut, bolt and part number is in there. There is a lot of detail,” Jesse said. “It wasn’t always like that. It started with an eight- or 10-page manual and grew to 35 pages. It was 40 some pages on the 2014 car and now it’s over 70 pages with photos and descriptions.”

The improved manual is great news for CJ owners, but the better news is that all the 2016 models should be finished in time for racing season.

The painted bodies return to Watson on carts for easy transport through the early stages of the assembly process where the car receives the remaining chassis mods, and the painting process is completed.

“We shipped 12 cars last year in 2015, and I want to say we have shipped eight or 10 to date in 2016,” Jesse said. “We plan to have all the cars built by March 1st.”

That means they should be ready to run in time for the likes of the NMRA’s Cobra Jet Showdown and the exciting new heads-up battle with the COPO and Drag Paks over at the NMCA.

“I’m excited about the NMCA Factory Super Cars class and the feedback I’ve gotten from numerous Cobra Jet racers in the NHRA has been positive. So I’m looking forward to this being a very successful class pitting the three manufacturers against each other,” Jesse added. “I can guarantee there will be a large Ford presence, and I am hoping there will be a real constituency from the Chevy and Mopar camps, and we can really make a show of it.”

Before the build process even began Watson gathers all the parts necessary to assemble 50 Cobra Jet racers. Many of the specialty parts, including all the unique metal bits, are built in-house at Watson. With all the parts inventoried and ready to go, the Cobra Jets can be produced in short order.

Among the parts necessary are 50 sets of front and rear wheel/tire combos. These cars roll on Weld drag wheels with 26×4.5-15 Hoosier front-runners and 30×9-15 Hoosier slicks.

The Cobra Jets are built at dedicated build stations with lifts, and rolling carts are used to move the larger parts assemblies into place. Engines and transmissions arrive in groups of five as needed so as not to take up too much space.

The painted bodies are fitted with the factory rear impact brace and the pre-painted rear fascia is installed.”

An essential step in the process is getting the suspension and drivetrain into the car. Here a DIB CJ gets its 3.89-geared Strange 9-inch axle and four-link rear suspension. Then the back Hoosiers are bolted up.

The entire front module is assembled and on a cart before being bolted into the Cobra Jet. That means the Whipple-supercharged Coyote (complete with American Racing Headers long tubes), electric power assist steering rack, lower control arms and more are all assembled before going into the car.

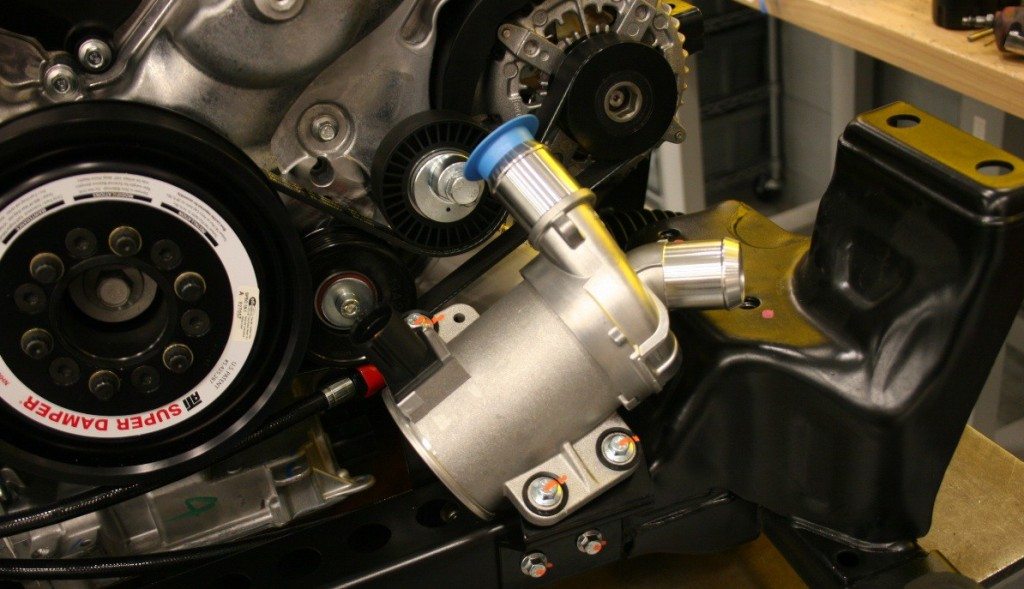

One of the innovations that we have covered previously on the 2016 Cobra Jet is the repurposing of the Ford C-Max Hybrid electric water pump on this race car. Not only does this pump move a lot of fluid, but it’s also rugged enough to meet Ford’s OE durability standards, so there is no worry about its ability to cool the Coyote down between runs.

The Cobra Jet Coyote is bolstered with a billet steel gerotor oil pump; Mahle forged pistons, Manley H-beam rods, ARP fasteners and an SFI-approved ATI crank damper. With stout internals and a 9.5:1 compression ratio this engine is ready to make the most of a Whipple 2.9-liter supercharger featuring an intercooler fed by a high-capacity water/ice tank.

After the assembly is complete, each Cobra Jet goes through an exhaustive inspection process before being deemed fit for delivery to the dealership. After each car passes quality control, it moves on to have graphics installed, and it’s ready to race.

2016 Cobra Jets have been built, but Ford Performance plans to have all 50 cars constructed by March 1, so we can look forward to seeing them all race this year!

FEB 18, 2016 | BY FORD PERFORMANCE STAFF

HERE IS HOW THE 2016 MUSTANG COBRA JET COMES TOGETHER

(PART 2)

Photos by Isaac Ireland

(This is the second in a two-part series on the construction of the 2016 Mustang Cobra Jet)

5.0L V-8 powers the 2016 Cobra Jet and the engines are built at Performance Assembly Solutions (PAS ) in Livonia, Michigan, and shipped to Watson Racing in batches. All 5.0-Liter Cobra Jet engines arrive at Watson on an engine pallet and are topped with a Whipple 2.9 Liter Cobra Jet Supercharger, a Ford Racing-engineered FEAD (Front Engine Accessory Drive), Cobra Jet Cams and Ford Performance Cobra Jet Valve Covers.

Once on the engine prep station, technicians install American Racing Headers’ long tube exhaust headers, flywheel, and the transmission. For 2016, Ford Performance equipped the engine with a race-prepped Joel’s On Joy C3 automatic transmission. After the engine/transmission is prepped for “decking” it’s placed in a movable fixture for attachment of the lower engine cradle, steering rack and lower control arms. Once the K-member, lower control arms, and front spindles are attached, the drag struts are installed complete with Strange Engineering lightweight brake rotors and two-piston calipers.

After the engine/transmission is prepped for “decking” it’s placed in a movable fixture for attachment of the lower engine cradle, steering rack and lower control arms. Once the K-member, lower control arms, and front spindles are attached, the drag struts are installed complete with Strange Engineering lightweight brake rotors and two-piston calipers. While the engine/front suspension is being prepped, the rear axle is being readied for installation. Strange Engineering built the Cobra Jet 9-inch unit and shipped as a ready-to-install item complete with rear disc brakes. For 2016 Cobra Jets, Ford Performance offered a 3.89 rear gear ratio.

While the engine/front suspension is being prepped, the rear axle is being readied for installation. Strange Engineering built the Cobra Jet 9-inch unit and shipped as a ready-to-install item complete with rear disc brakes. For 2016 Cobra Jets, Ford Performance offered a 3.89 rear gear ratio.

While on a two-post lift, the Cobra Jet body is raised for engine and rear-end installation. Once placed on the motor cart, the engine/transmission is rolled under the body, and the car is lowered while the engine is raised into the Cobra Jet engine bay. Once the engine and cradle are in place, the eight engine cradle bolts are torqued to spec. The transmission cross member is then installed on the transmission and attached to the frame mounts. Once the engine/transmission is secure in the chassis, the technician then moves to the rear end assembly and lifts the unit into the chassis. The upper control arms and lower control arms are attached and tightened to spec. The Cobra Jet uses tubular control arms with rubber bushings at all rear suspension attachment points. After the rear end is mounted, the rear coil-over shocks and Panhard bar are installed.

Once the engine/transmission is secure in the chassis, the technician then moves to the rear end assembly and lifts the unit into the chassis. The upper control arms and lower control arms are attached and tightened to spec. The Cobra Jet uses tubular control arms with rubber bushings at all rear suspension attachment points. After the rear end is mounted, the rear coil-over shocks and Panhard bar are installed.

After the rear suspension is in place, a Dynotech one-piece driveshaft is installed. With the Cobra Jet producing a bit more power than a Shelby GT350 and engineered to take repeated 7,000 RPM launches, a beefier one-piece Dynotech unit was selected. The final step after the decking station is the installation of the wheels and tires. The Cobra Jet has unique Weld Competition RT-S front 15”x3” wheels complete with a Cobra Jet Snake machined into the wheel spoke. Tires on the 2016 Cobra Jet Mustangs are from Hoosier, and the rear tire size is 30×9×15.

The final step after the decking station is the installation of the wheels and tires. The Cobra Jet has unique Weld Competition RT-S front 15”x3” wheels complete with a Cobra Jet Snake machined into the wheel spoke. Tires on the 2016 Cobra Jet Mustangs are from Hoosier, and the rear tire size is 30×9×15.

The final station is where the massive Cobra Jet air inlet tube and K&N filter are installed. After the air intake unit is complete, the car is ready to be moved to the alignment area for the first start, final check and drag race alignment.

Once on the lift, a Cobra Jet build team member starts the car for a systems check. All gauges are monitored for accuracy as well as engine sound. Once everything looks and sounds acceptable, the car is shut down for final calibration and prep.

While the car is on the lift the front and rear suspension is checked for alignment. To adjust the rear suspension, the alignment techs use the adjustable Panhard bar to center the rear end. For front-end alignment, the tie rods are adapted to bring the suspension into front-to-rear alignment specifications. After the alignment check, the cars are pushed to the decal application area for their unique Cobra Jet decal package. The base Cobra Jet decal package includes Cobra Jet quarter-panel script, CJ fender decals, and 5.0-Liter Cobra Jet hood decal.

After the alignment check, the cars are pushed to the decal application area for their unique Cobra Jet decal package. The base Cobra Jet decal package includes Cobra Jet quarter-panel script, CJ fender decals, and 5.0-Liter Cobra Jet hood decal.

While we visited the Cobra Jet assembly line, the build team was averaging three to four cars per day. Considering the complexity of some of the part installs and the hiccups that always arise, the team appeared enthusiastic to be a part of the 2016 Cobra Jet program. While we don’t know if any of the 50 cars will win an NHRA national event like John Calvert’s 2008 Cobra Jet, the 2016 version has several improvements over the previous models. While most cars are sold to collectors, we’re anticipating a few of these cars will hit the dragstrip early this year.

Don’t be surprised if one dips into the 8-second quarter-mile zone, not bad for a turnkey factory-built car.

Check out the full 2016 Cobra Jet Build at SVTPerformance.com

More articles of Interest on the 2016 Cobra Jet Build:

- Ford Performance >>

- 2016 Cobra Jet Build – SVTPerformance.com

- Ford Performance 2016 Cobra Jet Build Video >> Ford Performance

- Back for More – 2016 Cobra Jet >> SVT Performance

- Exclusive First Look! Ford’s 1,000hp Cobra Jet Mustang >> Hot Rod Network Magazine

- 2016 Cobra Jet Ford Performance Build >> SVT Performance

Videos of the 2016 Cobra Jet: